Smart Equipment Management for the Modern Repair Shop

EquipQR is the result of listening closely to the real problems that small, hardworking repair teams face every day. It bridges the gap between over-complicated enterprise ERPs and the paper-clipboards that most shops still rely on. EquipQR was designed not as software “for” mechanics, but with them — tested and refined by those who turn wrenches, not just keyboards.

The Challenge

3-A Equipment, a heavy-equipment repair shop in Texas, needed a simple yet powerful way to track their forklifts, generators, and tractors.

Their paper-based logs and scattered spreadsheets made it difficult to know:

- Which assets were due for preventative maintenance

- Who last serviced a machine

- What parts or seal kits were used

- Where a piece of equipment was located

They wanted a cloud system that felt purpose-built for small repair teams — fast to set up, easy to use in the field, and affordable enough for family-owned operations.

Our Solution

We designed EquipQR, a SaaS web app that turns every asset into a scannable digital record.

Each machine receives a unique QR code that instantly pulls up:

- Equipment history and specifications

- Maintenance schedules and work orders

- Images, inspection notes, and custom fields

- Assigned teams, locations, and status

EquipQR was built with small field service companies in mind — no bloated ERP complexity, no training required, and accessible on any device.

Key Features

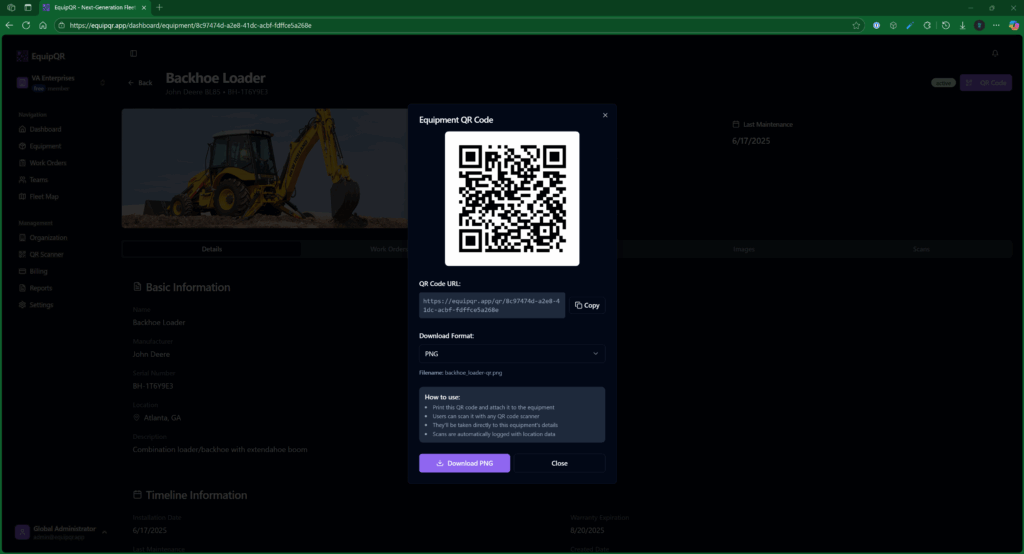

QR-Driven Equipment Profiles

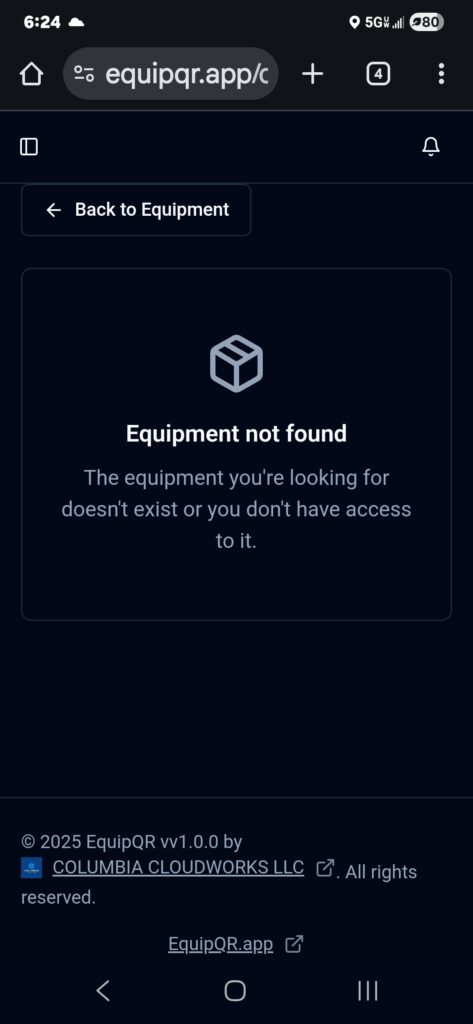

Scan to open a live equipment record in seconds. Unauthorized users receive an access-denied message if they attempt to scan a QR they haven’t been granted access to.

That means your QR codes can be safely placed anywhere — on machines in the yard, on-site with customers, or even in public listings. Only those you authorize can see what’s inside.

Each scan is logged with a timestamp and user identity, creating a secure audit trail for every access event.

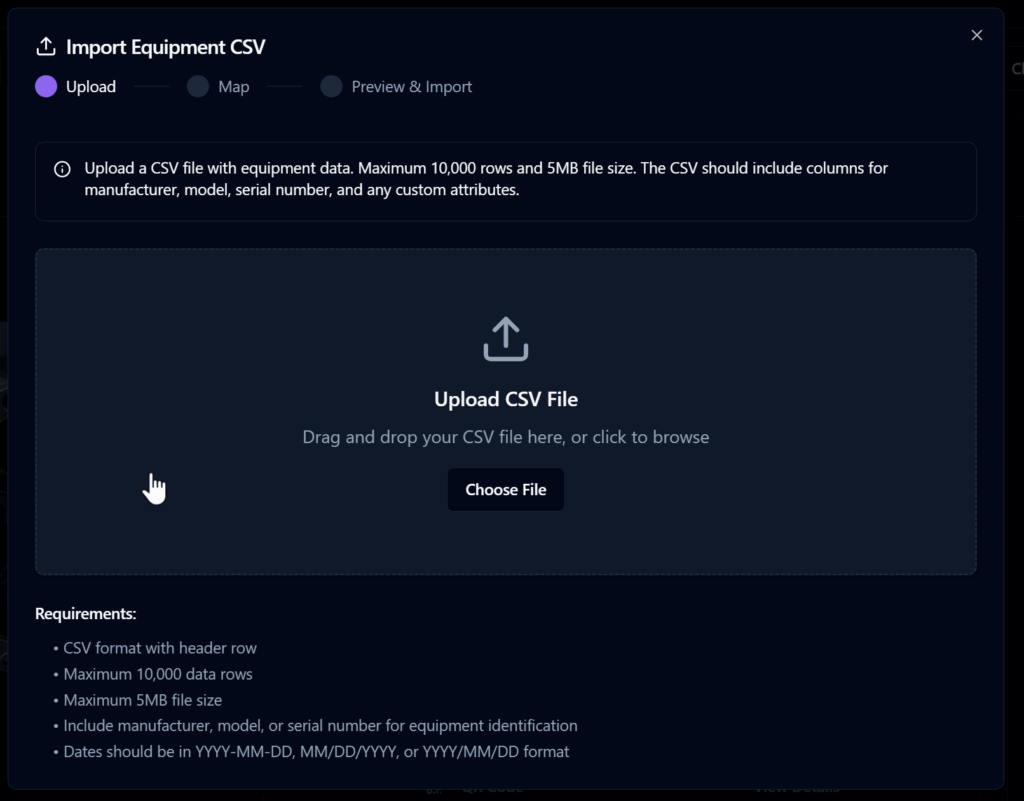

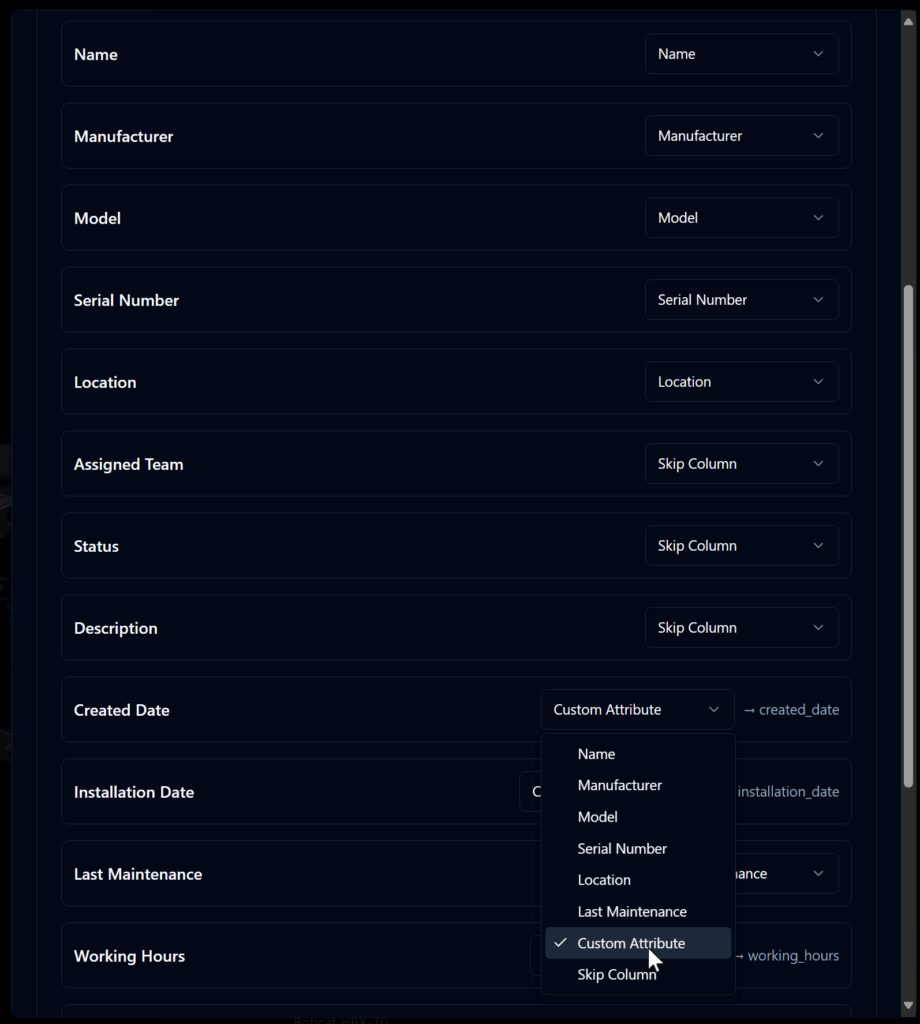

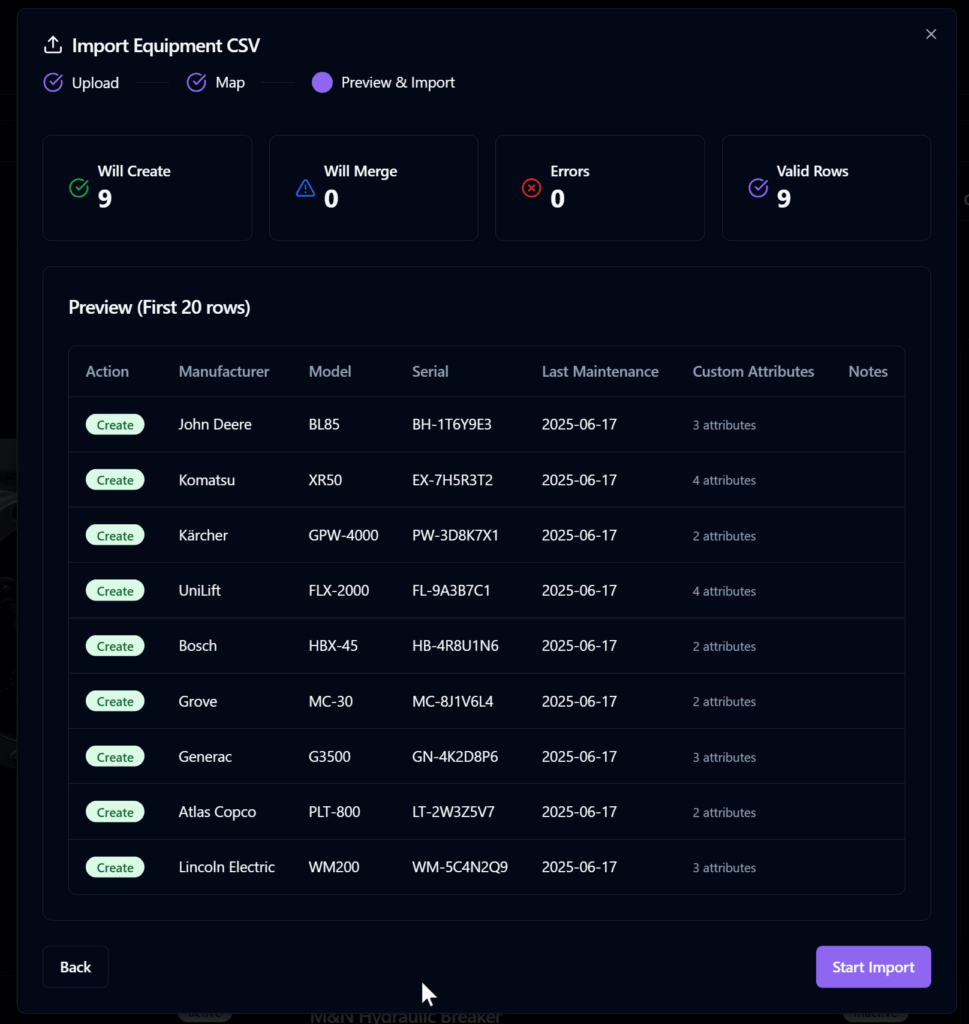

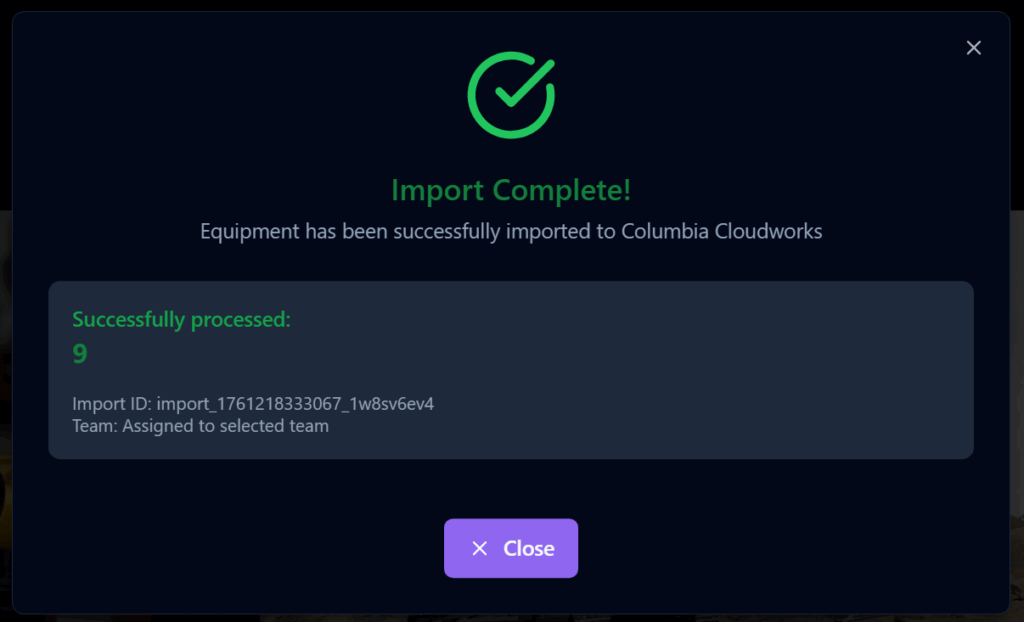

Easy Bulk On-boarding

Smart CSV import that learns your column mappings and helps categorize assets.

Whether you manage 1 asset or 10,000, you can upload an Excel spreadsheet containing every single thing you know about each machine.

One row per asset, one column per property — from horsepower to tire size to manufacturer’s manual URLs.

Work Orders & Preventative Maintenance

Create, assign, and track maintenance jobs with complete lifecycle visibility.

A single button press updates management, technicians, and even customers. Everyone stays informed without phone calls or follow-ups.

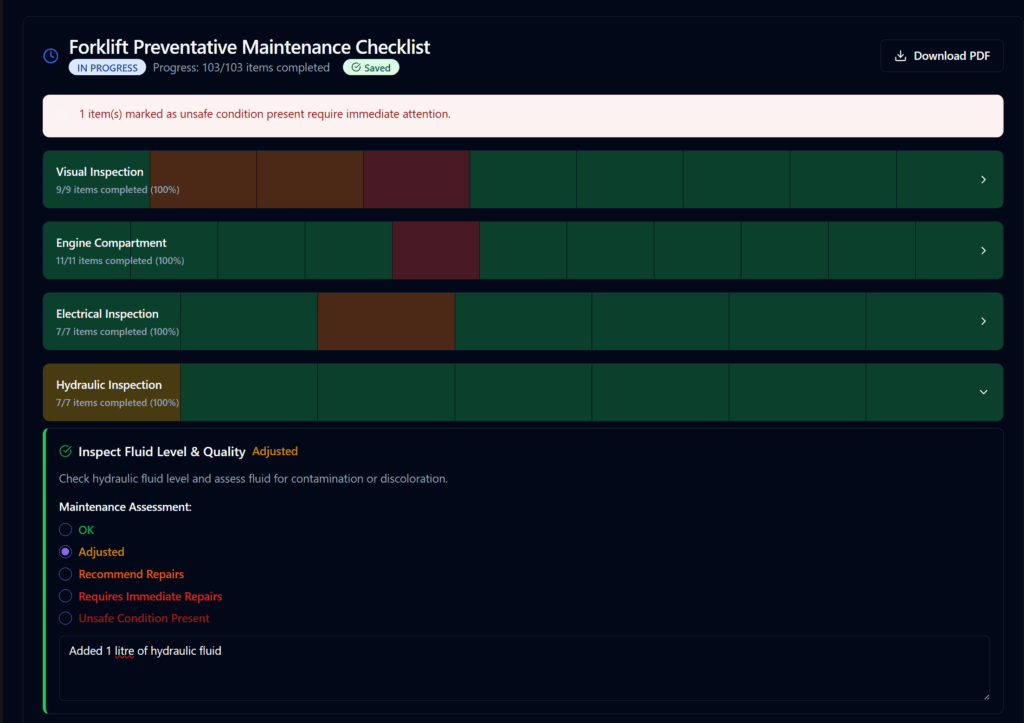

Our checklists are thorough, field tested, and tell you a complex story about the state of the equipment at a glance. A well trained mechanic will be able to see the color-coded checklist and deduce the problem as they notice patterns in the work over time.

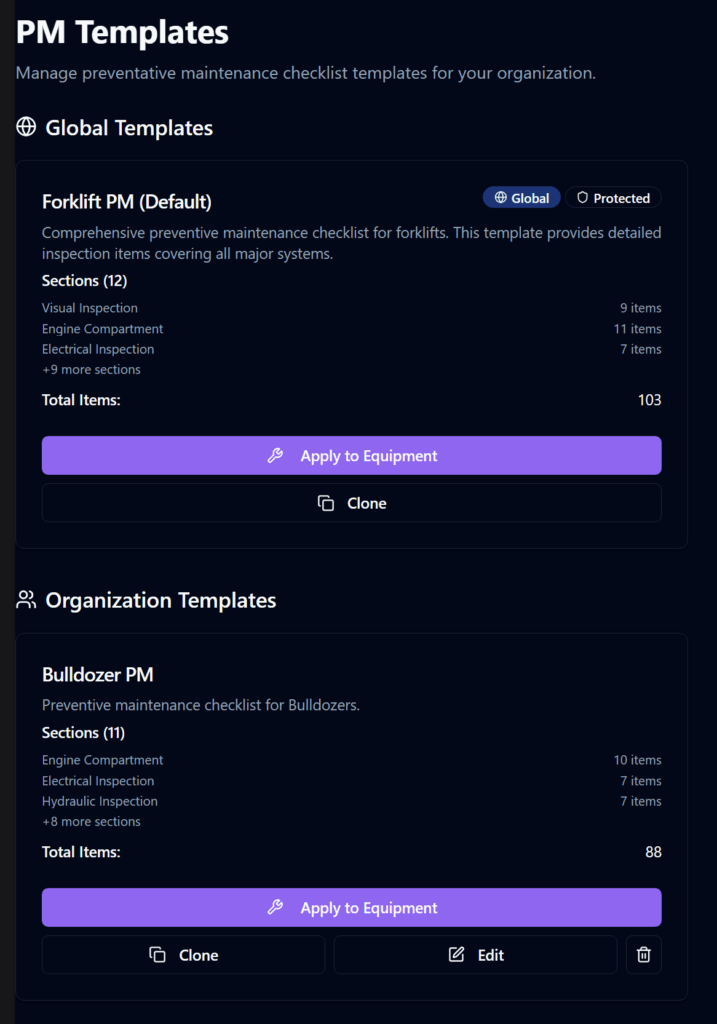

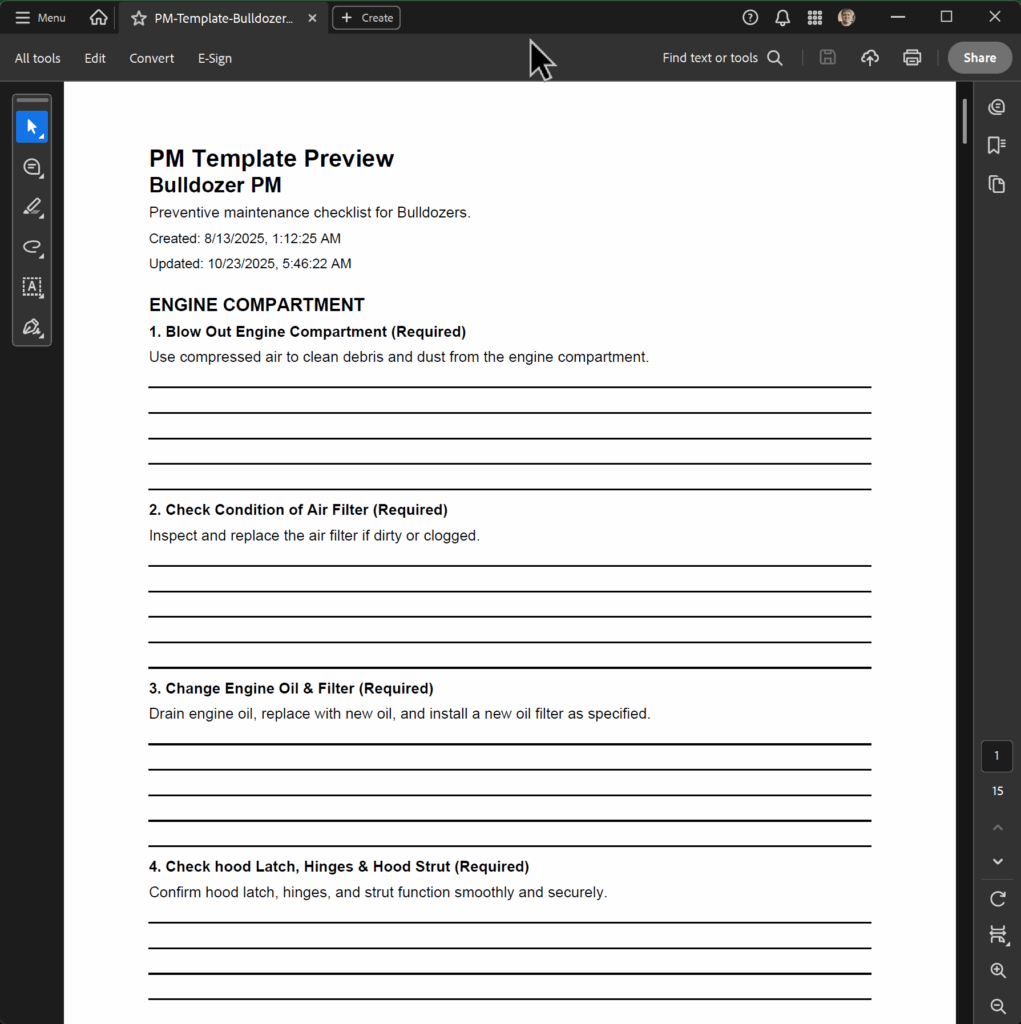

Custom Preventative Maintenance Checklists

EquipQR includes real-world preventative maintenance checklists built by and for working repair shops like 3-A Equipment and their partners. These aren’t generic templates — they’re proven workflows shared with the wider community so every shop can benefit from field-tested best practices.

Free users can attach these checklists to work orders right away to experience structured, professional-grade PM tracking.

For subscribed organizations (with at least one paid user license), these checklists become fully customizable. You can clone, edit, and extend any global template — or build your own from scratch — to match your exact equipment lineup and service process.

Prefer paper? EquipQR also lets you print any checklist as a PDF, perfect for technicians who still work best with a clipboard in hand. Simply hand them the forms, then have your office staff record results digitally afterward.

Team Roles & Permissions

Owners, managers, and technicians each see only what matters to them.

Technicians can add work notes — both public and private — while customers can only view what’s meant for them.

Cost breakdowns, internal comments, and service notes stay visible only to authorized roles.

This role-based access model keeps sensitive shop data confidential while still empowering transparency where it matters.

File & Photo Management

Attach inspection images, PDFs, and notes to each machine.

Photos and documents are securely stored in Supabase Buckets, preserving upload metadata — who uploaded it, when, and to which record.

Over time, every image becomes part of a living history of the equipment, providing undeniable context for warranty claims, service disputes, or resale documentation.

Fleet Map (Pro Add-on $20/month for your entire organization)

Visualize where your equipment is across job sites.

While EquipQR doesn’t use GPS trackers, it intelligently uses voluntary QR scan locations.

When a user scans a code and grants location permission, that data (with user, coordinates, and timestamp) updates the asset’s “last known” location.

This lightweight model saves cost and battery life while offering practical visibility — enabling shop managers to plan pickups, schedule technicians, and reduce unnecessary travel between sites.

Results

For 3-A Equipment, EquipQR replaced a cluttered system of clipboards and spreadsheets with one streamlined platform.

They now:

- Scan and update equipment from the shop floor or job site

- Log maintenance in seconds

- Track usage hours, inspections, and custom “Quick Hits” attributes

- Manage team accountability and customer transparency

Other service companies across industries — from construction to agriculture — can now adopt the same system out of the box.

Why EquipQR Stands Out

EquipQR isn’t just another inventory tracker.

It’s a field-ready digital logbook — combining the simplicity of a clipboard with the intelligence of the cloud.

It helps teams work smarter, not harder, by connecting people, equipment, and data through a single QR scan.

Make your shop smarter today.

Sign up for EquipQR for free and add your equipment today! Pay $10/month per user you add.